Contact us

- RECTANGULAR DUCTS

- CIRCULAR DUCTS

- AERAULIC ACCESSORIES AND CIRCULATION

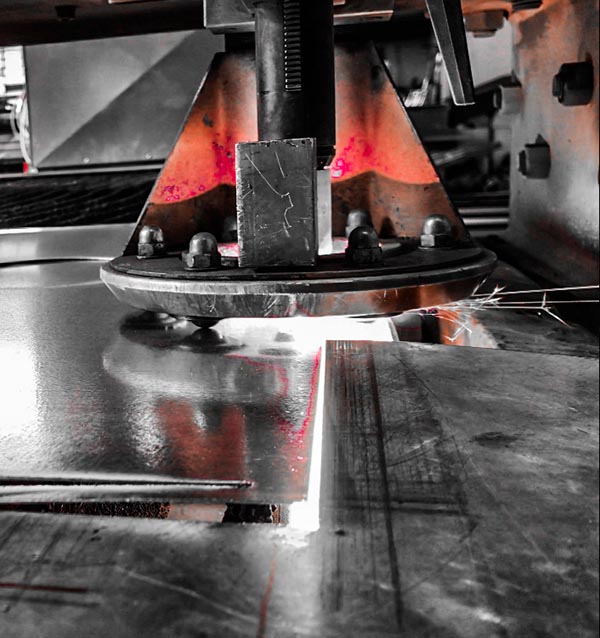

- PLASMA PROCESSING

- PROCESSING FROM COILS

- SHEET METAL PROCESSING

Our quality standards:

We manufacture rectangular aeraulic ducts; depending on the request, we can work with different metallic materials: galvanized sheet metal, copper, stainless steel, aluminized sheet metal, aluminum

Our quality standards:

We manufacture circular aeraulic ducts; depending on the request, we can work with different metallic materials: galvanized sheet metal, copper, stainless steel, aluminized sheet metal, aluminum

Our quality standards:

We manufacture fittings for aeraulic accessories; depending on the request, we can work with different metallic materials: galvanized sheet metal, copper, stainless steel, aluminized sheet metal

We also sell:

Our quality standards:

Our CNC (Computer Numerical Control) plasma cutting machine allows us to create any desired geometric shape

Our quality standards:

Our company invests in ongoing training and instrumentation, our products are reliable and accurate

Our quality standards:

Our company has more than 40 years of experience in the field of light carpentry processing

The experience gained through over 40 years of activity and research in the field of HVAC systems allows us to perform:

– routine maintenance operations such as filter replacement, and cleaning and sanitation of the Air Handling Units

– extraordinary maintenance operations in the Air Handling Units and Centrifugal Fans

– modify the AHUs (Air Handling Units), analyzing the status and designing the individual sections with their components: filter system, heat exchangers, ventilation sections, control system

Our company manufactures and installs aeraulic ducts, using the most modern CNC equipment

In order to guarantee the best performance levels and to prevent condensation in ducts, where necessary, we insulate the ducts with insulated sheets of the type and thickness indicated in the technical specifications of the client and/or the project, in accordance with the regulatory requirements

AEROTECNICA SATURNO can supply all the material needed to create a new controlled mechanical air conditioning and ventilation system, or to replace worn or damaged parts of the system

We can diagnose any problems in the systems, using certified instrumentation and offering the best possible solution